Glass Bottle & Jar Manufacturer | One-stop glass packaging solution

- Certified by international authorities

- -30℃ to 300℃ thermal shock resistance

- ISO 22000 certified Factories

- Low MOQ & free samples

Manufacturer to Nestlé & Unilever

98% On-Time Delivery

Wholesale Glass Bottles

Wholesale Glass Jar Categories

A variety of custom options available

As a glass container manufacturer, we offer one-stop customized solutions:

- 1. Consultation & Sketches

- 2. Design & 3D Modeling

- 3. Prototype Creation

- 4. Mold Creation

- 5. Production & Manufacturing

- 6. Accessories Production

- 7. Packaging & Delivery

- 8. Post-Production Support

Our Glass Packaging Solutions for Your 5 Key Production Challenges

As a leading borosilicate glass manufacturer and wholesale supplier, we engineer precision containers that solve critical food industry pain points. Our factory-direct approach ensures bulk buyers receive customized protection for their products.

1. Glass Contamination Risks

Heavy Metal Leaching/Alkali Dissolution

Our solutions

Technology Verification and Advantages

- Pharmaceutical-grade borosilicate glass formula

- Neutral glass inner coating technology

- Fully automatic laser impurity removal process

- SGS report: Lead and cadmium leaching <0.1ppm

- Passed FDA 21 CFR 174-186 migration test

- Reduced alkali leaching by 92%

“Solution for baby food glass bottles”

2. Filling line adaptation issues

broken bottles/stuck bottles/seal failure

Our solutions

Technology Verification and Advantages

- Bottle neck diameter tolerance control of ±0.05mm

- Patented anti-stuck neck design

- Vacuum induction automatic leak detection

- SGS report: Lead and cadmium leaching <0.1ppm

- Passed FDA 21 CFR 174-186 migration test

- Reduced alkali leaching by 92%

“Solution for baby food glass bottles”

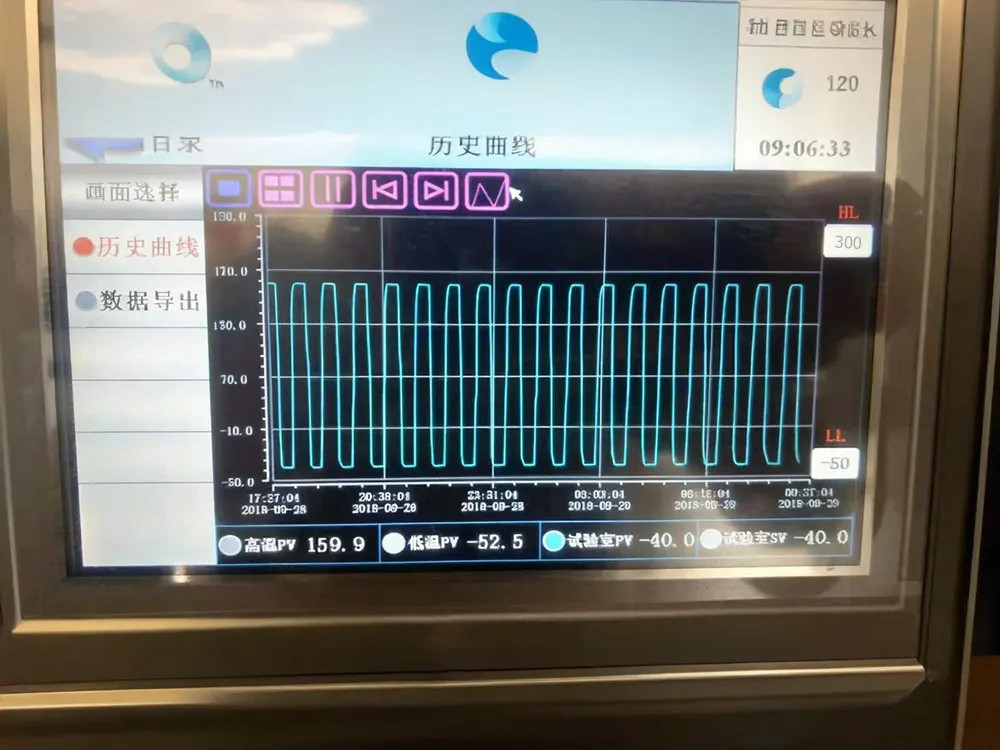

3. Temperature shock damage

Temperature shock damage

Our solutions

Technology Verification and Advantages

- Microcrystalline triple-layer glass

- Thermal expansion coefficient optimization technology

- Hot and cold alternating pretreatment process

- Passed Δ300°C thermal shock test (industry standard Δ150°C)

- -40°C to 300°C extreme environment certification

- Annual breakage rate of frozen food glass jars <0.3%

4. Inefficient customization

long development cycles/high communication costs

Our solutions

Technology Verification and Advantages

- 3D intelligent proofing system

- Dedicated customer technical support

- Modular mold database

- 3D digital prototypes available within 6 hours

- Sample delivery time reduced to 5 days

- Small order quantities available (MOQ 5,000)

5. Supply chain instability

Out-of-stock/delivery delays/inventory pressure

Our solutions

Technology Verification and Advantages

- 3-location bonded warehouse network

- Digital production dashboard system

- Emergency order processing channel

- 98% global on-time delivery rate

- 72-hour delivery to warehouse in Europe/North America

- 200,000 pieces of emergency production capacity reserve

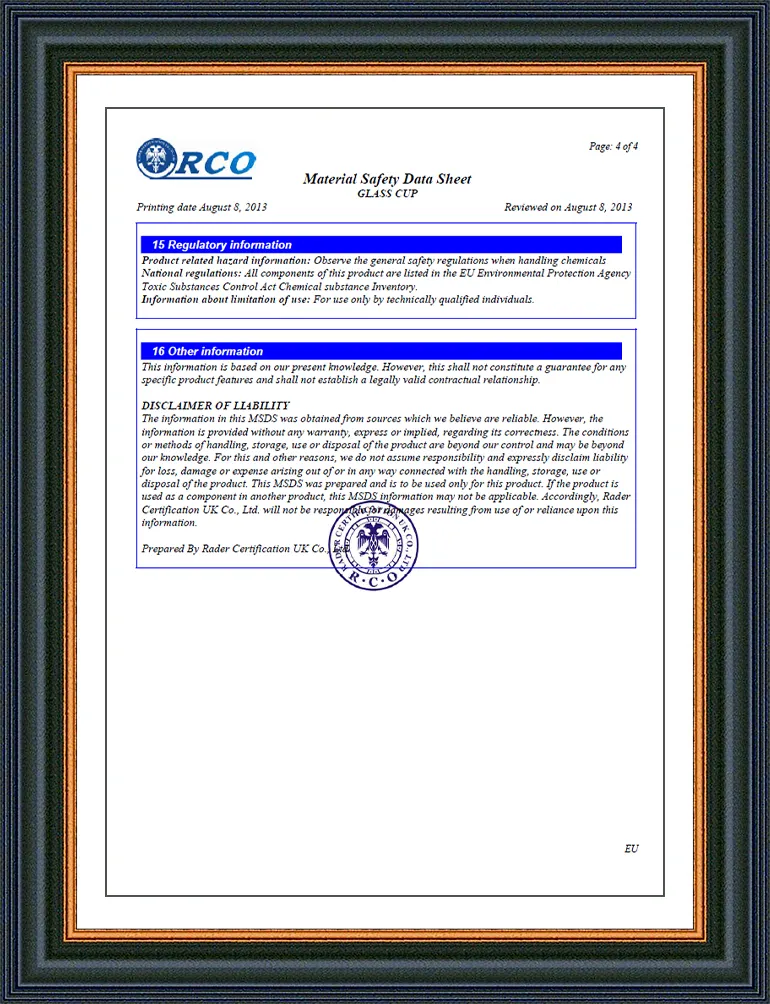

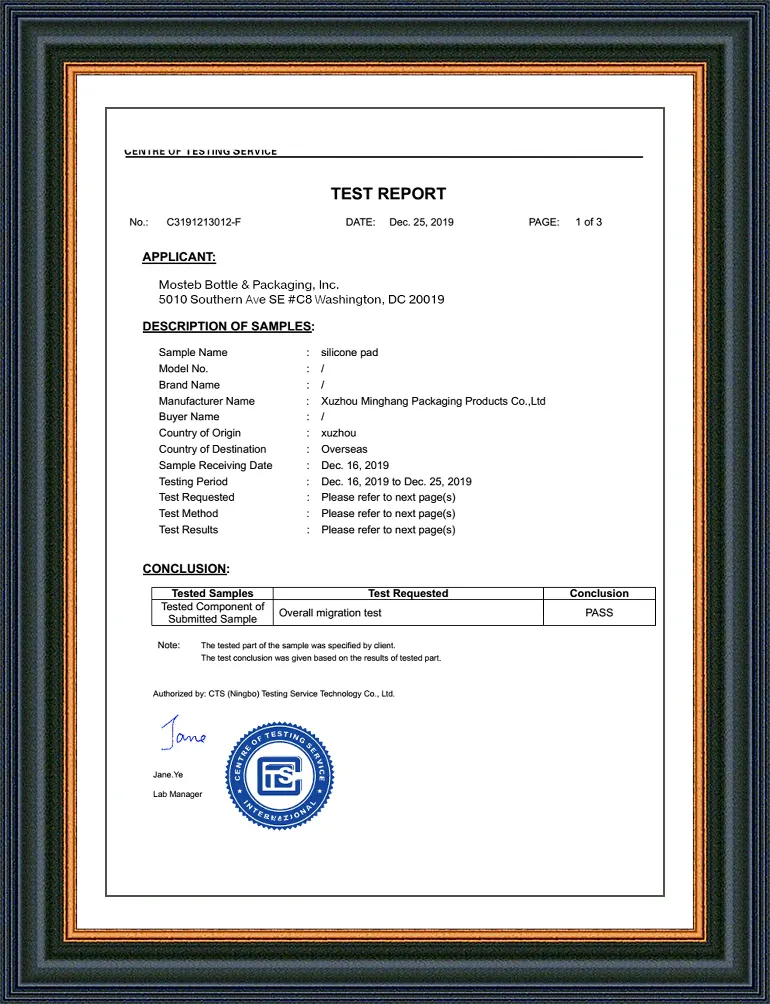

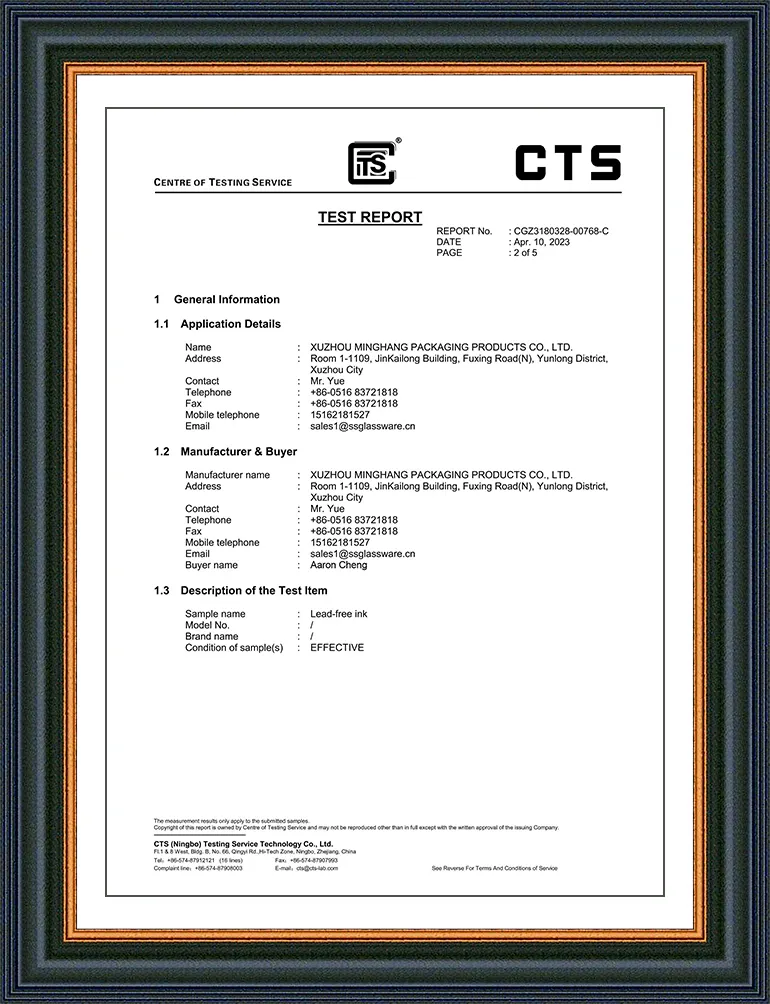

Authoritative Certification

What Our Customers Say

From gourmet food producers to beverage start-ups and cosmetic labels, our clients rely on us for reliable packaging solutions that reflect their brand quality.

“Your commitment to ECO-friendly materials and innovative designs notonly addressed our sustainability concerns but also set our bottles apart.”

Julienne lord

CEO of Wholesale Partner

“Your commitment to ECO-friendly materials and innovative designs notonly addressed our sustainability concerns but also set our bottles apart.”

Jascha Derr

purchaser of a leading beer brand

“Finding a supplier who understands our need for distinctive, high-quality bottles was tough until now, Exceptional service and productsthat truly resonate with our brand’s values!”

Kennedy Alter

Manager of supermarket chains